How To Install An Electric Gate Motor

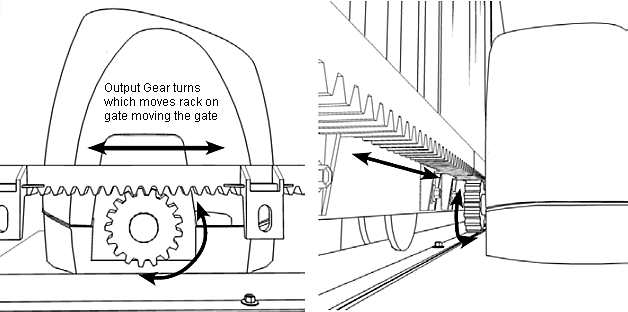

How Sliding Gate Motors work

The motor has an output gear that connects to rack on the gate, as the output gear turns the gate moves.

Preparing the Gate

The gate must open and close freely without binding anywhere forth the mode. Posts for sliding gates should be steel or seasoned hardwood that won't warp as this may crusade the gate to miss the keeper over fourth dimension and not work properly. If the gate has a guide post at that place must be at least 60mm (2 3/8") clearance for the rack, which is fitted to the back of the bottom runway of the gate. The motor needs a suitable concrete pad to be installed on that is level.

... READ MORE about installing pads for motors

Installing Cabling

If the motor is to exist powered past 240V mains you will need an electrician to take care of this. The motor can be hardwired where the power cablevision is feed through the pad the motor is fitted to or a Power Point tin can exist fitted next to the motor. If using Low voltage or solar power a depression voltage cablevision can exist feed through the motor pad and to a transformer or solar panel

... READ MORE on Power options for automatic gates.

Choosing the right motor

At that place is no such thing as one motor for all gates, different motors are suitable for different applications.

... READ More than about choosing the correct sliding gate motor.

Positioning The Sliding Gate Motor

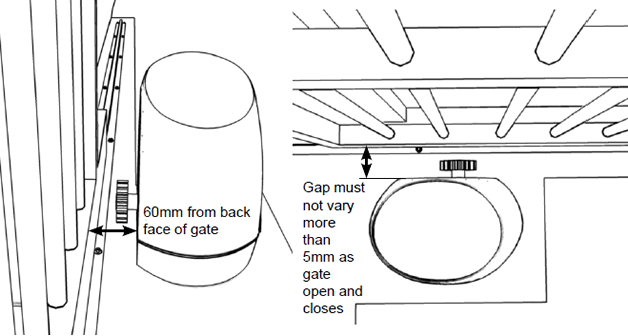

Place the motor on its pad about 60mm (2 3/eight") from the back face of the gate.

Place a length of rack on the output gear of the motor against the back confront of the gate to check that it lines up with the output gear correctly. Open and close the gate to see that this is consistent for the whole length of the gate. The bottom runway must be straight otherwise the spacing between information technology and the motor may very besides much and the rack non contact the output gear in places, which could stop the gate working.

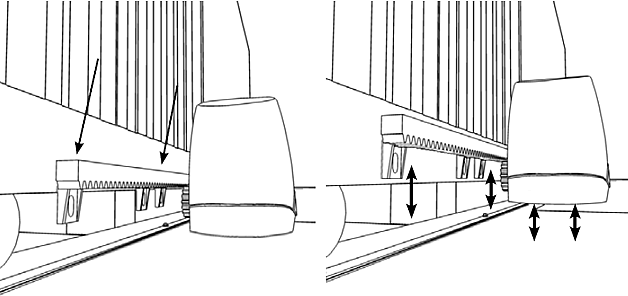

The rack must fit on the bottom rails of the gate for the entire open and close motility. If it comes off the bottom then the motor will need to be packed upward, if it comes off the top and so the gate wheels may need to be packed to elevator the gate higher or other means for fitting the rack may need to be implemented. The motor pad may also be lowered if necessary.

Fixing the motor to the Pad

Virtually sliding gate motors have a base plate that either bolts to the pad and and then the motor bolts to the base plate, although some motors bolt straight to the pad. Some Italian motors have bolt pins that are too be concreted into the pad, which isn't all that practical although these can exist replaced with normal bolts.

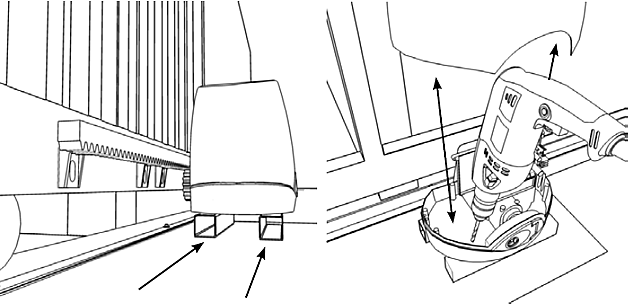

Packing the Motor up if needed

A couple of lengths of suitably sized box section aluminium or galvanised steel can be used to pack the motor upwardly. These would ideally accept holes drilled into them and then they can be dyna bolted to the concrete pad or metal screwed to a metal pad and then the motor screwed to the box sections where ever it tin exist.

It's important the the motor is fixed near the edges then information technology is firm and doesn't move at all when the gate is moving.

Fitting Rack for a Sliding Gate Motor 1

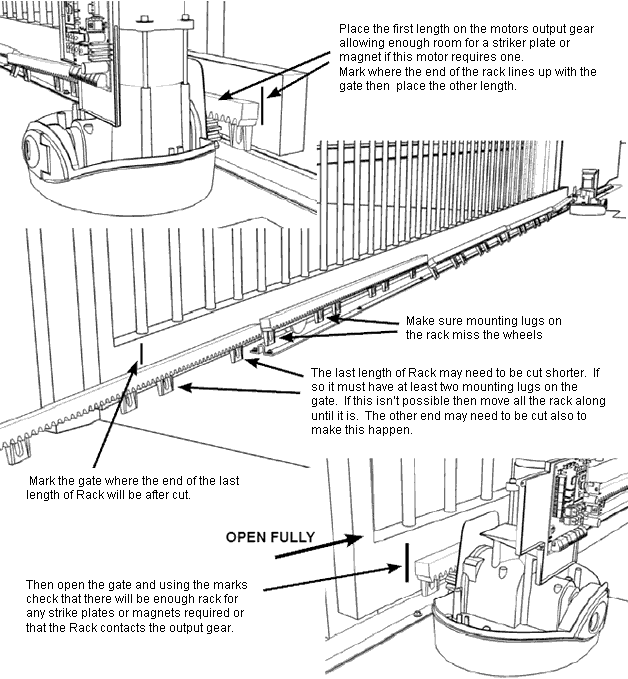

Before fitting the rack lay information technology out behind the closed gate to see how it will line upwardly.

Plumbing equipment Rack to the Sliding Gate Motor 2

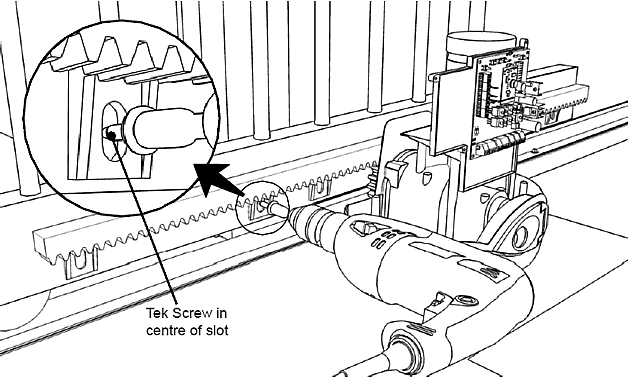

To fit the rack start with the gate well-nigh closed and place the first length of rack on the motors output gear aligned with the mark made previously on the gate. Using an electric drill attach the rack using tek screws in the centre of the slots in the mounting lugs.

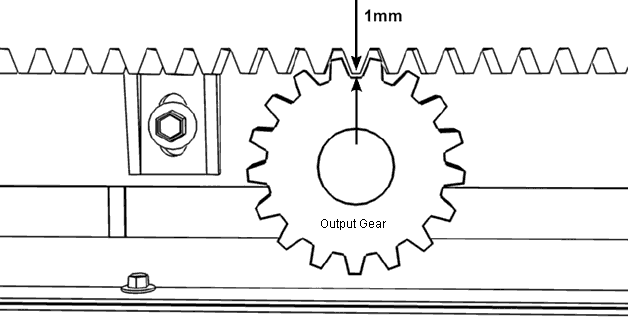

Adjust the height of the rack above the output gear so at that place is a gap of about 1mm (ane/25").

Plumbing equipment Rack for a Sliding Gate Motor 3

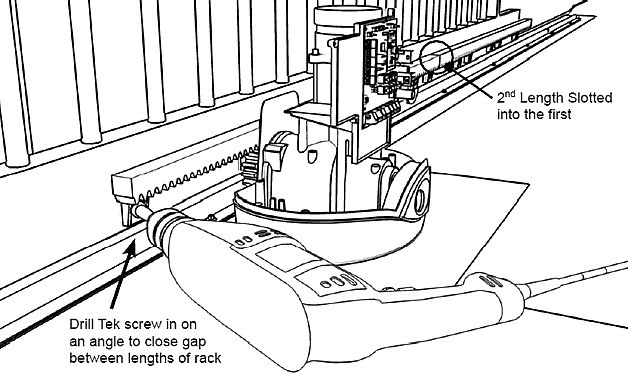

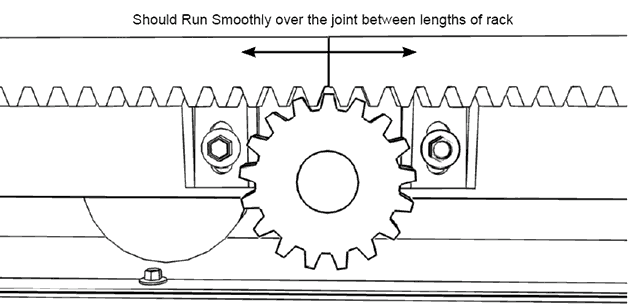

When plumbing equipment the second length of rack make sure the that information technology is firmly clipped together then the tooth spacing is consequent at the bring together, other wise the gate may jump when the joint goes over the output gear.

Plumbing equipment Rack for a Sliding Gate Motor 4

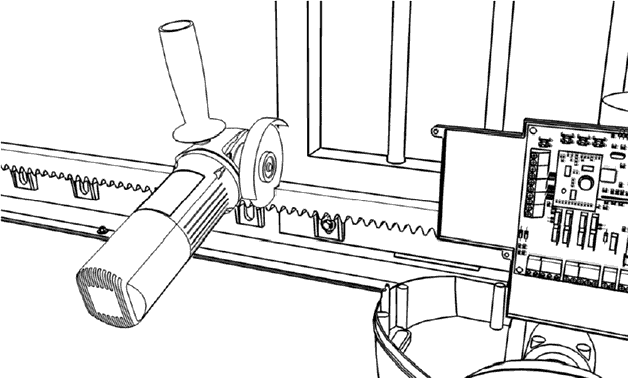

In one case all the lengths of rack are fitted cut the last one to length if necessary using an bending grinder with a steel cutting bract considering the rack has a steel rod in the middle.

How to go it all Working

Exercise not connect any photocells, digital keypads, intercoms etc... yet, get the gate working without these outset to reduce confusion if something'south not working correctly. Power up the motor then set the remote controls.

... READ MORE nearly how to set remote controls to work on your motor

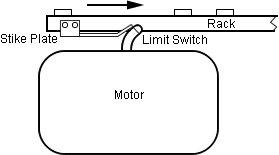

And then set the open and shut limits for the gate. There are different methods for determining where the fully open or closed position of a sliding gate is. The virtually mutual using strike plates fitted to each end of the rack that contacts a spring loaded wand sticking out of the motor that activates limit switches inside the motor.

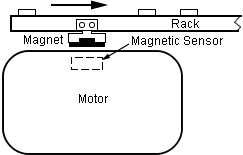

Other motors use magnets instead of striker plates with a magnetic sensor in the motor. At that place are besides motors that utilise one only magnet placed near the closing end as a reference only not a limit. These also accept an 'encoder' that is a rotation counter of the motor used to make up one's mind how far the gate moves between the fully open up and close positions with the reference marking making sure it stays on runway.

Once the strike plates or magnets are fitted all motors need to run through a learning process that powers the motor open and airtight to learn where the limits are. Y'all will need to refer to the installation transmission on how to do this as it is dissimilar with each motor.

Now connect accessories one at a time and test their functioning such as Photocells, In Ground Vehicle Detector, Digital Keypad, Intercom etc...

Source: https://www.grantsautomation.com.au/index.php?page=61

Posted by: grimmwomighon.blogspot.com

0 Response to "How To Install An Electric Gate Motor"

Post a Comment